Chapter 11

I The Present Energy Economy

II Australian Energy Consumption

III Research And Development

IV Coal

i Transition at the coal face

ii Further development of face mechanisation

iii Mechanisation outside the face area

iv Open-cut mining in NSW

v Open-cut mining in Queensland

vi Underground mining in Queensland

vii The state of the art

viii Conclusion

V Oil And Natural Gas

VI Solar Energy

VII Nuclear Energy

VIII Bagasse Firewood And Other Biomass

IX Electric Power Generation And Distribution electric Power Generation And Distribution

X Manufactured Gas

XI Industrial Process Heat

Sources

Index

Search

Help

Contact us

Transition at the coal face

In 1947 Australia produced 14.5 million tonnes of raw black coal, of which 11.7 million was from NSW and 1.5 million from Queensland. By 1986 the figures had become: Australia 164 million tonnes, NSW 77 million and Queensland 80 million. These figures will help to convey an appreciation of the way advanced technology, or mechanisation as it is more generally referred to, played a part in establishing in Australia an innovative and highly productive industry which can be classed as at least the equal of any of the major producing coal countries in the world. In doing this it will be necessary to make some mention of the industrial problems which beset coal mining in the State of New South Wales and that State will be used to trace the development of mechanisation, as that is the State where the major developments took place and which remained the highest producer until eclipsed by Queensland in 1985-86.In this comparison two convenient time frames have been used, namely 1947 and 1986. The year 1947 was chosen because prior to that, although mechanisation had long been recognised as one of the main salvations of the industry, no attempts to establish it had met with success. The main reason for this was the legacy of industrial dispute inherent in the coal mines, stemming from the use of convict labour from the inception and, later on, the importation of British miners who were well aware of the onerous conditions that existed in their own mines in the early 1800s.

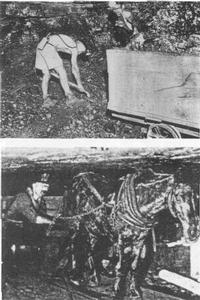

From the start of coal mining operations in Australia coal was hand filled into skips or tubs and either hand-propelled or horse-drawn to its destination in the mine and this continued until 1935, when the first mobile coal loading machine was installed in NSW. Opposition to mechanical loading was due to many factors, principally loss of employment and also the probable loss of the contract system which still operated; in fact in 1945 only 26 per cent of the coal mined underground was mechanically loaded.

4) Horse haulage was common in 1935. Horses were either taken out of the mine each day or stabled underground and brought up at the weekend.

To prepare coal for loading prior to 1935 it was necessary to undercut the seam initially by pick and later by machine and then bore holes in the face for the introduction of explosives, the detonation of which produced a manageable heap for the hand filler to work on. The transition from hand work to machines required a power source, which at the present time is provided by electricity, so that it could possibly be said that true mechanisation commenced when electricity was used to drive a motor driven pump in the Co-operative Colliery in 1893 although a coal cutting machine, a Stanley Header, driven by compressed air was installed at Greta in 1890. Thus mechanization first appeared in 1890. However, progress was slow, old customs die hard and the mining union's employment fears were such that by 1925 the percentage of coal cut by machines was only 20.5 per cent as against the USA of 70.6 per cent.

|

Australian Academy of Technological Sciences and Engineering |  |

© 1988 Print Edition page 787, Online Edition 2000

Published by Australian Science and Technology Heritage Centre, using the Web Academic Resource Publisher

http://www.austehc.unimelb.edu.au/tia/758.html